PRODUCTS & SERVICES

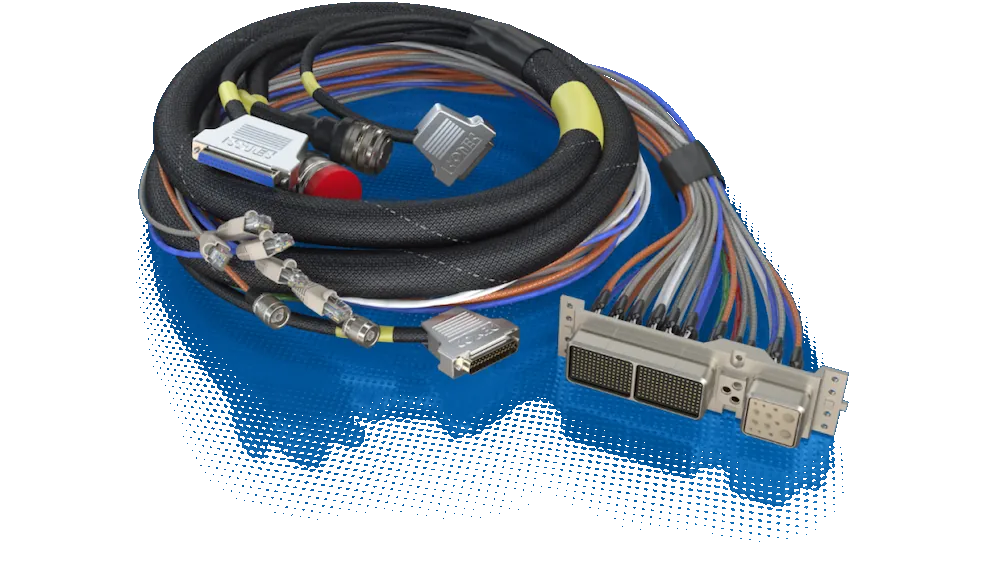

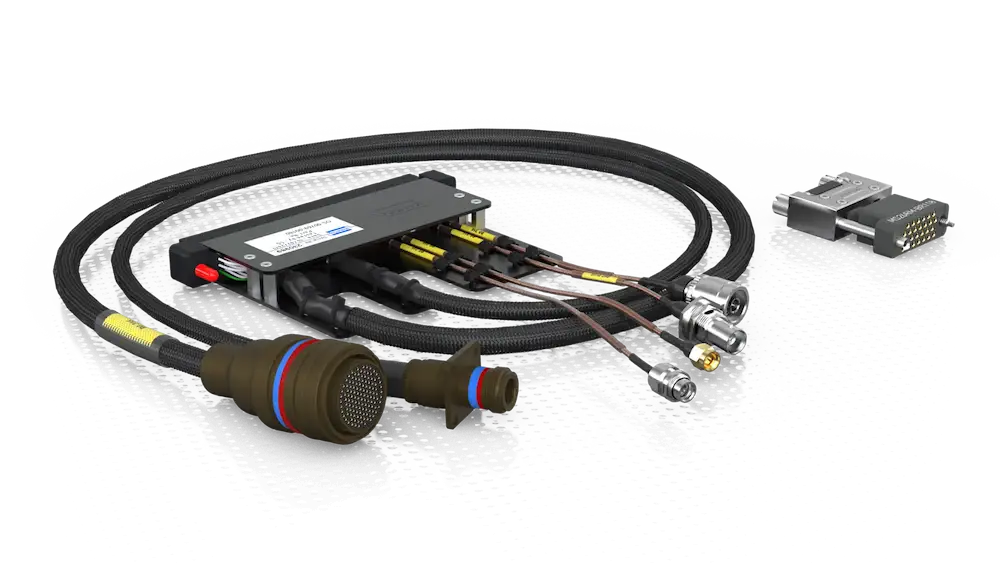

Tailored to your needs, we build cable assemblies based on your exact specifications, materials, or requirements for special components.

WHY CHOOSE US

Pickering Connect specializes in bespoke cable assembly and connectivity solutions with quick turnarounds for any project size. Our innovative Cable Design Tool and in-house expertise ensure precision and speed. Trusted globally for over 20 years, we have nurtured a reputation for excellence, reliability, and value, serving a diverse range of industries with reliable products.

The first step to creating a custom cable with us is to use our free, easy-to-use online tool.

TEST SYSTEM ARCHITECT

TSA is our in-house platform where your approved cable design becomes the single data source for everything that follows. The same data underpins our shop-floor tools and test procedures, so every build – and every reorder – can be checked against your original specification.

Thanks to our tool, the design process is easy and intuitive, whether you draw the cable yourself or let our engineers handle it. Furthermore, your data becomes the source for the manufacturing documentation and the pin-out tests to ensure your cable is built correctly.

Cable Build Assistant pulls data about your design from the Cable Design Tool to drive production tools on the shop floor, guiding every connection step by step so even complex custom cables are built right the first time.

Every cable assembly leaving our facility is thoroughly tested – including 4-wire measurements, hi-pot testing up to 2 kV DC and pin-out verification against the original specification – to help prevent field failures and unpleasant surprises.

CONNECT CAPABILITIES

At Pickering Connect, we blend our decades-long engineering expertise with innovative technology to deliver custom cable assemblies designed to meet the exact needs of our customers. Our core capabilities include:

Our innovative Cable Design Tool is at the very foundation of every cable assembly built at Pickering. This intuitive and visual tool lets you create, save, and organize your projects seamlessly. It has all the features needed for designing fully functional cable assemblies, including a vast library of connectors, wires, and backshells, the ability to collaborate on a design or chat with our cable technicians. Best of all, it´s free and runs in your browser with no installation needed.

Wire processing is a critical step in cable assembly, involving cutting, stripping, crimping, and terminating wires to precise specifications. At our facility, we offer comprehensive services that include:

Automated single wires processing and termination

Semiautomatic multiconductor processing machine

Coaxial Cable Stripping

Wire termination capabilities

Marking technology

We offer the option to customize single or multi-core cables and their various features to meet your specific requirements.

Custom single-core conductors:

Custom multi-core cables:

Additionally, we offer whole reel twisting.

All cables undergo thorough testing, including 4-wire, up to 2KV HiPot, and various other tests tailored to client specifications.

Our advanced testing equipment allows us to run a wide range of both low and high-voltage tests. This includes high voltage dielectric withstand (DW) and insulation resistance (IR) testing, as well as detecting error locations for opens and shorts. In addition, we can test built-in components to ensure the cable’s overall performance.

What we test on our cables:

With our CNC capabilities, we can offer fully customized aluminum backshells tailored to your specific requirements. Our capabilities allow for rapid prototype development, ensuring high-quality and durable solutions.

Overmolding Capabilities: Provides a cost-effective alternative to traditional backshells.

Potting: Enhances durability by filling the complete electronic assembly with a solid or gelatinous compound.

Thanks to our own PCB department, we can seamlessly integrate PCB and cable components. For instance, we can transform connectors designed for circuit boards or panels into fully functional cable connectors. We offer comprehensive services that include:

Are you working on a prototype system and still haven’t decided on the final pinout?

Or perhaps you need to add components like resistors, LEDs, capacitors, etc. to your cable?

Do you have a design ready and need a quote, or want to ask a question? Send it our way, and we’ll get back to you as soon as possible.

All products manufactured by Pickering Connect are warranted against defective materials and workmanship

Have a design drawing and don’t want to redraw it in the Cable Design Tool? Simply send it over, and we’ll handle the rest.