.jpg)

Custom Backshell Design

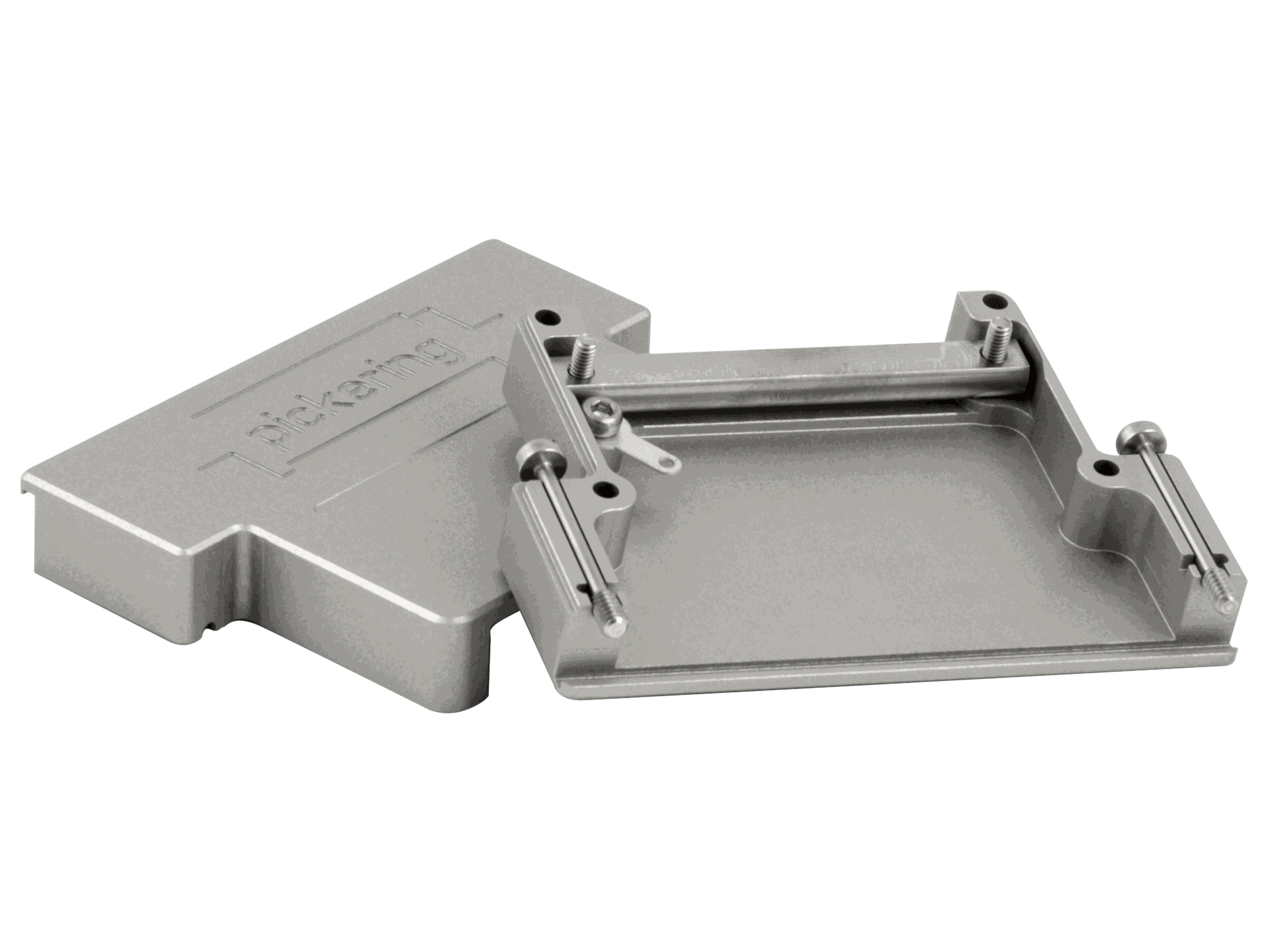

During our 15+ years as a designer and manufacturer of custom connection solutions we have experienced a number of limitations with proprietary connector backshells, for example, backshells that would have been perfect for a particular application couldn’t be used because the cable exit holes were too small, or different screwlocks were required.

With investment in in-house 3D mechanical design and CNC machinery, these limitations no longer exist—we can design and manufacture backshells in any size and in any shape, and all in high-grade anodized aluminium.

Custom backshells can be ordered from low to medium quantities and provided in a turnaround time of just a few days.

During our 15+ years as a designer and manufacturer of custom connection solutions we have experienced a number of limitations with proprietary connector backshells, for example, backshells that would have been perfect for a particular application couldn’t be used because the cable exit holes were too small, or different screwlocks were required.

With investment in in-house 3D mechanical design and CNC machinery, these limitations no longer exist—we can design and manufacture backshells in any size and in any shape, and all in high-grade anodized aluminium.

Custom backshells can be ordered from low to medium quantities and provided in a turnaround time of just a few days.

Examples of Previous Designs

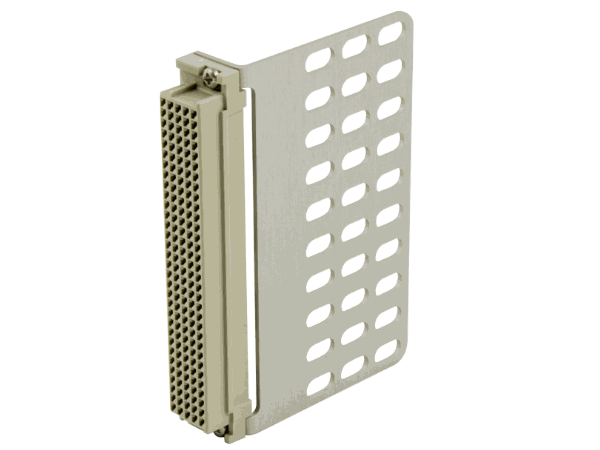

Strain relief plates

We also offer custom designs of strain-relief plates, which are a cheaper alternative to a full connector backshell.

104 Pin D-Type

We offer a 104 Pin D-Type connector backshell.

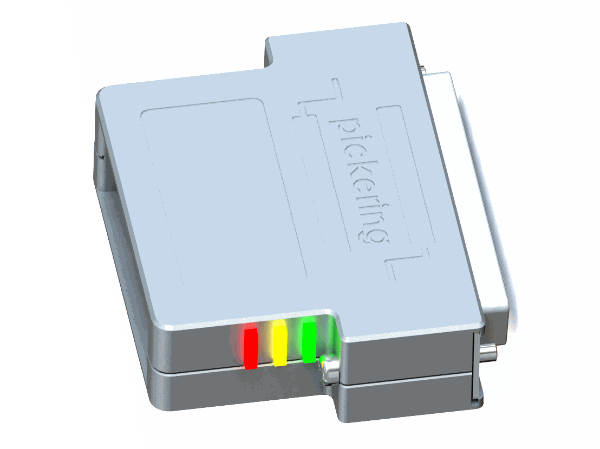

Built-in backshell parts

We can modify our range, or any other manufacturer's backshell made from aluminium or plastic to fit any parts you need. Would you like LED diodes, banana plugs or dubox connectors fitted into backshell?

No problem for us.

We make all modifications in-house so there is no lead time.